Close

Menu

With over 200 years of combined experience we think it’s safe to genuinely call ourselves branding experts! With an incredible varied range of products and services we think it’s critical that we have a complete understanding of all types of branding methods. We want to share our expertise, knowledge and understanding for all embellishing methods so you also have a better idea which is the appropriate branding method for your requirements. Remember every product may have a different branding method so it’s critical we have the expert inside track of all processes to help you create a world class image for your company, campaign, team or organisation.

Manufacturing has been at the heart of Wild Thang since 1996 and you are more than welcome to pay us a visit at any time to get the official guided tour and find a little more about how we work and how that brilliant branding ends up on the printed promotional incentive, engraved corporate gift, screen-printed t-shirt, branded football jersey, embroidered uniform, digitally printed pull up banner or business card! We are very proud to still be manufacturing in the UK.

We hope that this area really does give you peace of mind that regardless of the branding method we are here to help with expert advice.

Read more

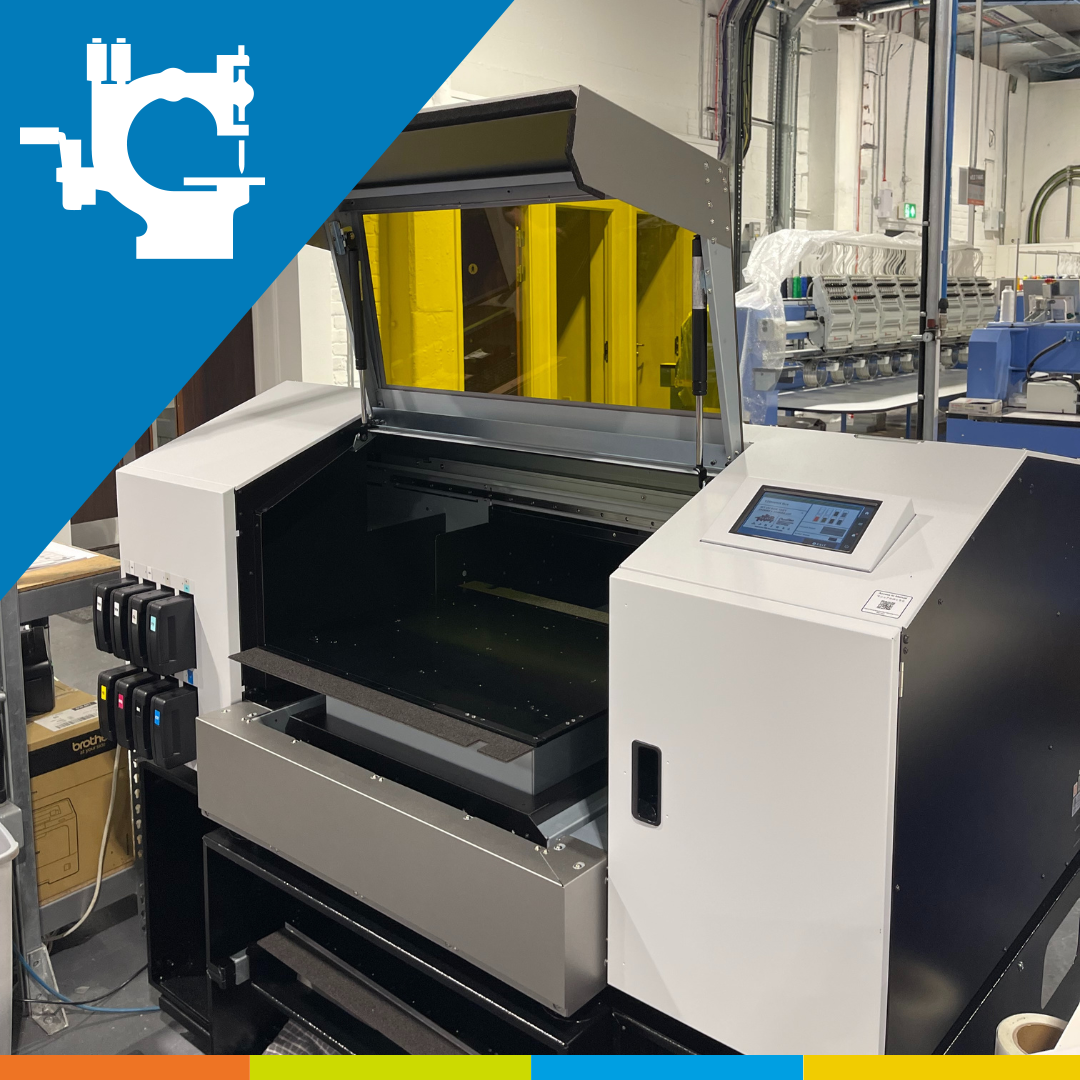

UV PRINTING

UV printing is a cutting-edge branding technique that uses ultraviolet light to cure specially formulated inks directly onto a wide variety of surfaces. At Wild Thang, our investment in advanced UV print technology has further elevated our in-house capabilities, allowing us to deliver ultra-precise, high-quality prints with incredible 3D relief effects. This method is perfect for branding complex shapes, hard goods, and promotional merchandise where traditional methods may fall short. Whether you're looking to add a tactile, high-impact finish to a premium gift or create detailed designs on unusual surfaces, UV printing offers unrivalled versatility and vibrancy. Fully integrated into our world-class production facility, UV printing helps us push creative boundaries and provide truly bespoke branded solutions that stand out from the crowd.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

Direct to Film, or DTF, is one of the latest innovations in garment branding and offers incredible versatility when it comes to applying vibrant, full-colour designs onto a wide range of fabric types. This method involves printing your design onto a special film, which is then transferred directly onto the garment using heat and pressure. At Wild Thang, we’ve embraced DTF for its exceptional print quality, durability, and ability to reproduce complex artwork, even on difficult materials. It’s an ideal solution for both small and medium production runs where detail and colour vibrancy are essential. DTF is fast becoming a go-to branding method for promotional merchandise, sportswear, and fashion-forward clothing ranges, and forms a key part of our ever-growing branding capabilities.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

We believe our in house State-of-the-Art Screen printing machinery is essential if your design is to be faithfully reproduced. Our professional team of screen printers are highly experienced in printing a wide variety of fabrics and substrates on items such as t-shirts, hoodies, shoppers, umbrellas, rulers, posters, bags, scarves, caps, table clothes, car stickers and much more besides.

Having produced work for some of the biggest and best corporate, sports and retail companies you can rest assured we will deliver world class quality products and service. Perfect for sportswear, corporate uniforms, promotional, leisure, work wear and a variety of other merchandise products.

Did you know the branding method of silk screen print was first invented in China during the Song Dynasty (960-1279AD), now that’s what I call old school printing and although the concept of forcing ink through a silk mesh screen to create the print is the same, the technology and accuracy of the equipment used today is vastly different. A photo sensitive layer will be applied to the screen on which the artwork or logo is exposed under UV light then set up on either a manual, automatic carousel or flat bed. Also a specialist pen or mug machine with the finished printed product being either heat or UV cured. We have invested over £100,000+ in the very latest screen print technology with a capacity to print in excess of 50,000 garments per week, we are at the forefront of textile screen printing to recreate the highest of retail standard achieved with designs boasting exceptional clarity and vibrancy. Pantone colours can be matched to your colour requirements while bringing an on trend and high-street fashion retail look to life using inks, glitter, flock, puff, glow in the dark, reflective and more.

There is always the option of Wild Thang providing trade printing services with you supplying the garments or product for contract screen printing. We have contracts in place to produce work for many high profile sports teams, fashion labels, companies and sports brands and will always try to be an extension of your team to deliver the very finest print quality in turnarounds that work for you.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

If it’s good enough for Rolls Royce and Lamborghini leather seats, you can be confident in achieving the very best quality embroidery finish for your brand. Using the very latest technology. Our In-house embroidery department is fully self-sufficient and specialises in authentically reproducing your logo, crest or name as accurately as possible. We have invested circa £200,000+ to be at the forefront of embroidery branding.

Did you know Embroidery has been dated to the Warring States period (5th-3rd century BC) of ancient China? The process used to tailor, patch, mend and reinforce cloth fostered the development of sewing techniques, and the decorative possibilities of sewing led to the art of embroidery. Embroidery has certainly come a long way since then and our state of the art machines can now do over 1000 stitches a minute.

The process begins with your logo being digitized into a file format the embroidery machine can read. The calculation of costs is based on how many stitches are required to recreate the branded logo. Once approved and ready to proceed a ring is put on two sides of the item to hold it securely in place and then fixed on the machine, then the magic can happen! Pantone colour matching is not available but close colour matches are possible from the huge range available.

All embroidery orders will have a sample produced for you to approve, so only when you're 100% happy do we proceed with the full order.

This process allows multicolour decoration of flexible fabrics by using a needle and threads. Usually chosen for its hardwearing longevity properties, embroidery has a distinct look often reflecting a certain level of professionalism and brand quality. We have the knowledge for all the latest techniques including 3D embroidery and we can use virtually any fabric from felts to leathers to create an awesome jaw dropping appliqué finish.

Having produced work for some of the biggest and best companies you can rest assured we will deliver world class quality products and service. Perfect for sportswear, corporate uniforms, promotional, leisure, workwear and a variety of other merchandise products.

The choice is yours, whether we supply the garments or you supply the garment for contract embroidery. We have contracts in place to produce work for many high profile sports teams, fashion labels, companies and sports brands and will always try to be an extension of your team to deliver the very finest quality in turnarounds that work for you.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

We have the very latest technology in a variety of transfer applications with a capacity to print and apply using the very latest semi-automatic heat presses, meaning very large quantities can be produced in timescales that will amaze you. We have invested substantial amounts of money to be at the forefront of transfer printing to faithfully recreate the highest of retail quality for your brand. Transfer printing is an alternative to screen-printing that is generally used when the material, garment or product is not suited to a direct screen print. This does not give a lesser quality process but a specialist branding method that is used equally as much as any other method in the modern day.

The design is applied to transfer film and then heat sealed onto the garment. Transfer printing is the term used to describe textile and related printing processes in which the design is first printed on to a flexible non textile substrate and later transferred by a separate process to a textile material using a heat press. The heat and pressure from the press will make the glue adhesive create good adhesion between the two substrates creating the required bond. Once the transfer is cooled off, the paper is removed and the logo will remain on the item.

Did you know that the first transfer had the initial intent of moving a pre-made image from one location to another and to serve as an essential substitute for ink? In 1801, an Italian inventor, Pellegrino Turri, invented carbon paper to provide the ink for his mechanical typing machine, one of the first typewriters. Ralph Wedgwood obtained the first patent for carbon paper in 1806. Wedgwood's ceramic technique was then continuously perfected and now today this process relates to many transfer applications including fabric.

We have the expertise to produce many different forms of transfer including screen printed transfer, digitally printed transfer or lithographic print transfer. Vinyl and digitally printed contour cut transfer technology is yet another alternative which is accurate and efficient, meaning perfect results even on short runs. This makes us able to produce low and personalised designs at affordable prices. Cut vinyl involves computer-controlled equipment precisely cutting shapes from sheet vinyl. Vinyl is commonly used for applying personalization - think of the names and numbers on the back of football shirts as just one example of how this method of branding is utilized.

Having produced work for some of the biggest and best corporate, sports and retail companies you can rest assured we will deliver world class quality products and service. Perfect for all types of garments and merchandise.

There is always the option of Wild Thang providing transfer printing and application services with you supplying the garments or product for our team to brand. We have contracts in place to produce work for many high profile sports teams, fashion labels, companies and sports brands and will always try to be an extension of your team to deliver the very finest print quality in turnarounds that work for you.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

This is a permanent, unchangeable and precise personalisation and is obtained with laser engraving on different types of material, although the best results are seen on metal products. The laser technique is where the surface of the branded item is eliminated and the colour of material below determines the colour of the personalization meaning the print cannot be removed. This is a luxurious look, especially on shiny metal it can recreate extremely detailed designs and even individual personalization is possible (via Excel files). No chemicals are needed in the process meaning it can easily be produced on an extensive range of materials including Metal, Aluminum (colour of the logo is always white), Wood (is a natural product so not all engravings will be the same) Glass (most of the engravings will be white) Fleece (engravings will be a bit darker than the fleece) Felt, Leather, some (hard) plastics, Paper and Polyurethane (PU).

Did you know the first evidence for humans engraving patterns is a chiselled shell, dating back between 540,000 and 430,000 years, from Trinil, in Java, Indonesia, where the first Homo erectus was discovered? Hatched banding upon ostrich eggshells used as water containers found in South Africa in the Diepkloof Rock Shelter and dated to the Middle Stone Age around 60,000 BC are the next documented case of human engraving. Engraving on bone and ivory is an important technique for the Art of the Upper Paleolithic and larger engraved petroglyphs on rocks are found from many prehistoric periods and cultures around the world.

A digital logo will be sent to the laser machine, then with a light beam (YAG laser) or a gas beam (CO2 laser) the top layer of the material will be “burned” away. And the logo becomes visible. The more complex the logo or the bigger the surface we need to engrave, the longer the production time. A simple line of text may take 5 seconds but a square of 10x10 cm may take a minute or more per piece.

Items that are perfect for this branding method are Business card holders, Key rings, Pens, Wine boxes, Desk clocks and believe it or not garments can now be laser engraved to give that alternative discreet branding method.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

We think if you have the same budget and resources it is all about looking at what the well established brands are doing, whether it be Hugo Boss or Top Shop, they all create ranges that include the finishing touches that make their specific brand stand out from the crowd.

We know sometimes the devil is literally in the detail. When it comes to uplifting value in clothing nothing could be truer. Garment or merchandise finishing is all about elevating your products, giving them the small retail finishes or packaging to give it that bespoke look is what the discerning customers have come to expect and will pay extra for.

The better it looks the more perceived value it creates and that’s why we think it’s important to put the retail finish to your range. Finishing details such as high quality woven or printed brand neck or hem labels, PVC badges, Zipper pulls, locker patches, hem clips, swing tags and even bespoke packaging bags or boxes. We can even now directly screen print to the inside of the neck or produce a transfer so you get better comfort for your customer and branding opportunity. These small extra production costs can swing a large upward increase in perceived retail value.

We have thousands of products that all have generic brand labels such as Gildan, Fruit of the Loom, Hanes, American Apparel and many others all of which are quality garments. Although there is no comparison that if you hang one garment next to another that has had the retail treatment, by unpicking and sewing in a bespoke label, all of a sudden it becomes a completely different higher quality item and sits side by side perfectly next to any other bespoke brand elevating your products on the hanger. Swing tags can not only be attached to garments but also other merchandise products such as hampers, bags etc if you want to add an additional personalisation or even write something personally.

Did you know that you can probably thank the Federal Trade Commission for the most important labels and tags on your clothing? Yes, the ones that tell you how to care for a certain type of fabric. Federal law slowly started to regulate how clothing items were designated, first with the Wool Products Labeling Act of 1939, which required labels to designate whether a product is made of certain kinds of wool. A 1951 label, targeted at fur, further helped encourage the use of labelling on different products. Today this is a requirement on every garment produced but we know it’s now more important that the brand itself has aspiration and how that brand is perceived.

Finishing is all about making the greatest possible impact and we’ve spent years focusing over all the finer details, so whether it’s to really make your retail rock, your campaign or music merchandise drop dead gorgeous or make that kick starter campaign offer really stand out from the crowd.

Please remember we are here to help with expert branding advice.

Read more

We have the latest digital printing technology and equipment which covers a vast range of materials and applications, there really are endless opportunities to produce eye-catching full colour small and large format printed displays. Digital CMYK print process delivers sharp images on low print runs. Printing something as simple as a promotional banner using a standard large format digital printer or a small notepad that requires full colour branding using a special UV digital printer to imprint directly onto the item. Inkjet print heads move above the material or item and create images. At the same time a UV lamp dries the ink if required. The printer can print CMYK colour mode but also white. The printer heads can be adjusted in height so even thicker items can be printed by use of this technique as long as the surface that needs to be printed is even and flat.

Did you know the very first machines were developed for fine art? Digital inkjet printing which evolved from digital proofing technology from Kodak, 3M, and other major manufacturers, with artists and other printers trying to adapt these dedicated prepress proofing machines to fine-art printing. There was experimentation with many of these types of printers, the most notable being the IRIS printer, initially adapted to fine-art printing by programmer David Coons and adopted for fine-art work by Graham Nash at his Nash Editions printing company in 1991.

Digital Printers can print onto a variety of materials can such as vinyl, plastic, metal, wood, paper, imitation leather and glass. As well as a variety of standard products such pull up banners and exhibition displays, it is now possible to even print items like wine boxes, sliding puzzle games, lids, notebooks and is also Ideal for paper insert products.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

High-volume lithography is used presently to produce posters, brochures, books, newspapers and packaging onto just about any smooth, mass-produced item. Print and graphics are now printed using offset lithography achieving high quality photo realistic reproduction of your designs. There really are endless possibilities when it comes to choosing the perfect print design, paper and finish method for your organization, brand or campaign.

Did you know Lithography was invented by Alois Senefelder in the Kingdom of Bavaria in 1796? In the early days of lithography, and much like fine art lithography today, a smooth piece of limestone was used.

After the oil-based image was put on the surface, a solution of gum arabic in water was applied, the gum sticking only to the non-oily surface. During printing, water adhered to the gum arabic surfaces and was repelled by the oily parts, while the oily ink used for printing did the opposite.

Modern printing plates are now used, the image on the plate is created by direct laser imaging using a CTP (Computer-To-Plate) device known as a plate setter.

So whether it’s a simple flyer for mass distribution to a high quality brochure to give to your very best clients to create a world class first impression, we are here to help with expert branding advice.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

This is the method of engraving a logo or brand into a metal stamp, the logo is then pressed into the material of the item. Embossing and debossing are the processes of creating either raised or recessed relief images or designs in paper and other materials. An embossed pattern is raised against the background, while a debossed pattern is sunken into the surface of the material (but might protrude somewhat on the reverse, back side).

Embossing pressure and heat combined on material leaves an impression, the material has to be thick enough to withstand the pressure of the machine and the surface has to be even and flat.

There are 2 real options, one is using a foil material in gold, silver or a variety of other colours allowing the foil to adhere to the product or the second option is blind embossing without foil creating an elegant finish for diaries, conference folders and notebooks, leather goods, even clothing can be debossed to create a more subtle finish.

Let’s say Yee-ha to branding because debossing and old-fashioned cattle branding have a lot in common. Both involve the use of a customized metal plate to essentially make a stamp. And this stamp indicates that Bessie the Cow, or in this case your promotional item, is the property of your business. Did you know that, like advertising, cattle branding goes back to the early days of civilization? It’s true! There’s evidence that the ancient Egyptians were branding their cattle as early as 2700 BC. Today, when ranchers mark their cattle, they use a highly regulated system of registered brand designs... just the way you are when you put your trademark logo on a promo item!

Just so you know which materials can be printed, they include leather, polyurethane (PU), paper or card carton. There is a good variety of products that can be branded using this method such as document folders, wallets, business card holders and notebooks. It’s useful to remember there are a limited number of colours possible and pantone colours can’t be matched.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

We have a great knowledge of direct-to-garment printing often referred to as simply DTG, in many ways this is not dissimilar to full colour digital printing but uses a flat bed and inks that are specially manufactured to be suitable for garment material. This is a new and constantly developing technique which is perfect for creating stunning multi-colour designs in very small volumes, providing the only realistic way of producing retail grade bespoke one off designs on dark garments.

The tradeoff between the flexibility of DTG is the speed of production which can be slower than that of traditional screen printing on higher volumes. However attempting to create a full colour design on just a few items with screen printing is sometimes not economically feasible for the client.

DTG removes the upfront costs of screen stencil setup therefore finally making multi-colour short runs commercially viable. DTG is a big part of the branding future and is likely to compliment screen printing as an alternative process.

Did you know direct to garment printing began in the United States in 1996 with the introduction of the first commercially available DTG printer named “Revolution” developed by DIS of Bradenton and based on an invention of Matthew Rhome.

Mr. Rhome had been working on the DTG project for some years prior to release and applied for a patent in July 1996. This patent was granted by the US patent office in August 2000 making it the first DTG patent and solidifying Mr. Rhome as the founder of the DTG industry.

DTG can print onto a variety of clothing in a variety of positions and if you wanted to design a range of clothing and sell online there is even an option to create a drop ship portal, meaning when the order is placed it is printed on demand.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

Pad or Tampo Printing is the process of ink being transferred using a pad made from silicone or rubber taken from a metal plate that holds the logo. This involves laser etching of a specialized polymer plate, in simpler terms it is literally a big rubber stamp, dipping it in ink, and stamping products over and over until the order is complete. The big rubber stamp is called a pad by those in the printing industry, this industrial process means pad printing come in all sizes and shapes like pointed, rectangular, and round. This allows products of nearly any size or shape to be customized with pad printing. The pads vary in density, too. Some are extra-firm, while others are best described as squishy so a more awkward shape can still be branded making it Ideal for products with an uneven surface.

Did you know while crude forms of pad printing have existed for centuries, it was not until the twentieth century that the technology became suitable for widespread use? First gaining a foothold in the watch-making industry following World War II, developments in the late 60s and early 70s, such as silicone pads and more advanced equipment, made the printing method far more practical. The ability to print on formerly unprintable surfaces caught the imaginations of engineers and designers, and as a result pad printing exploded into the mass production marketplace.

Today, pad printing is a well-established technology covering a wide spectrum of industries and applications great for materials such as Plastics, Polypropylene (PP), Polystyrene (PS), Polyethylene (PE), PVC, Metal and in some cases even glass, ceramic and wood. This branding wonder can print virtually any kind of shape/item in the world which is why it’s probably the most used printing technique in our business. Pens, desk clocks, business card holders, USB sticks, ceramic mugs, memo clips, key chains… you name it round or flat, everything is possible, however the material of the item or the limited printing size can result in having to switch to a different printing technique.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

Doming is an extremely durable and can resist scratches and fading through a crystal clear resin type coating.

Used on any flat surface including keyrings, USB's and badges. The term doming comes from the rounding that is reminiscent of a dome. On a digital printer the logo is printed to a high resolution on a roll of adhesive paper, a cutter will cut out the desired shape and then a 2 component resin layer, the epoxy, is applied. This layer is crystal clear, this means not only will the logo be protected against colouring also it looks slightly enlarged and is protected against scratching. Doming is formulated to be self-leveling which is the perfect viscosity for most applications for epoxy decorative coating.

Believe it or not originally used for dental fixtures, epoxies were invented in the 1930s by two scientists, Dr. Pierre Castan in Switzerland and Dr. Sylvan Greenlee in the United States. The first epoxies were amber coloured solids but soon became widely available as adhesives. Today, more than 50 different substances known as epoxy resins are available and used in a wide range of different applications, epoxy doming being one of them.

In essence this covers any item where the surface is flat and suitable to put a sticker on, materials such as metal, wood, leather, plastics, Polyurethane (PU) make the perfect branding partner for items like name badges, key chains, pens, folders, sweet confectionary tins and wine boxes. If you have a product they can also be used as a semi-permanent sticker.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

Sublimation is a digital print technique using special inks, the first part of the process is when a special transfer paper is digitally printed with the image, the paper is then placed on a polyester surface or other substrate such as ceramic or coated aluminum, then a heat press will be used to transfer heat and pressure. At this point the ink is literally transferred from the paper into the materials.

Did you know the very first machines where developed as fine art digital inkjet printing which evolved from digital proofing technology from Kodak, 3M, and other major manufacturers, with artists and other printers trying to adapt these dedicated prepress proofing machines to fine-art printing.

There was experimentation with many of these types of printers, the most notable being the IRIS printer, initially adapted to fine-art printing by programmer David Coons, and adopted for fine-art work by Graham Nash at his Nash Editions printing company in 1991.

There are probably a lot more applications than you first realise, such as, a large number of sport kits are printed this way. Think, football, rugby, cycling, in fact I think its safe to say that the majority of technical polyester fabrics are printed this way. We can produce Feather Flags, Bow Banners or Teardrop Flags, branded table cloths or cushions for your reception. Think ceramics, such as mugs, aluminum coated bottles and badges and you soon start to see how important this process is to so many industries which ultimately is aimed at making that perfect first impression.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

We have got adhesive stickers galore, we can produce fully custom self-adhesive stickers that are great quality, at low prices and a huge range of shapes and sizes. Your order will be printed with 1440dpi high definition digital printing using lower-eco impact solvent inks for stunning detail, vivid colour and tough durability. There are a wide range of finishes available with customisation options to tailor your adhesive labels to your precise needs and budget. When it comes to vinyl sticker finish, you can choose from various die cut sticker shapes, on a plotter, the logo is printed on a roll of sticker paper then a cutter will cut out the desired shape and the stickers are ready for use. Once printed they can be applied to virtually any item to promote your company brand or message.

Did you know stickers were first used in the 1800s? Once upon a time European merchants decided that it would be a smart idea to attach eye catching labels to their crates of goods in order to attract the attention of passers-by. These labels detailed the goods on offer as well as prices and were originally attached using gum paste, and therefore adopted the name ‘stickers’.

During the 1900s the technique was developed and a paste was formulated that would, once applied to the back of a label, dry and then its ‘stick’ would be activated when moisture was applied. Postage stamps adopted this technique as well as travel companies who would attach these labels to passenger’s luggage as a form of identification.

In 1935 R. Stanton Avery invented the first self-adhesive and the Avery Company continues to be a world leader in the sticker/label industry today.

Most businesses have to mail items to their customers or suppliers and by creating your own branded labels, your company can make a positive impression and help your envelope or parcel climb to the top of the post pile. Think of how many car stickers you may have seen over the years and how great stickers can look when added to packages and boxes to give that little extra finishing touch. Stickers can also be applied to a variety of other products such as short run personalized lolly pops, when you think about it the opportunities are literally endless.

Got a question? Get in touch and remember we are here to help with expert branding advice.

Read more

The history of printing goes back to the duplication of images by means of stamps in very early times. The use of round seals for rolling an impression into clay tablets goes back to early Mesopotamian civilization before 3000 BCE, they feature complex and beautiful images. In both China and Egypt, the use of small stamps for seals preceded the use of larger blocks. In China, India and Europe, printing on cloth certainly preceded printing on paper or papyrus. The process is essentially the same, in Europe special presentation impressions of prints were often printed on silk until the 17th century. The development of printing has made it possible for books, newspapers, magazines, and other reading materials to be produced in great numbers and it plays an important role in promoting literacy.

We just love this timeline and puts into perspective just how long this business of branding has been going on

| Woodblock printing | 200 |

| Movable type | 1040 |

| Printing press | c.1440 |

| Etching | c.1515 |

| Mezzotint | 1642 |

| Aquatint | 1772 |

| Lithography | 1796 |

| Chromolithography | 1837 |

| Rotary press | 1843 |

| Hectograph | 1869 |

| Offset printing | 1875 |

| Hot metal typesetting | 1884 |

| Mimeograph | 1886 |

| Photostat and rectigraph | 1907 |

| Screen printing | 1911 |

| Spirit duplicator | 1923 |

| Dot matrix printing | 1925 |

| Xerography | 1938 |

| Phototypesetting | 1949 |

| Inkjet printing | 1951 |

| Dye-sublimation | 1957 |

| Laser printing | 1969 |

| Thermal printing | c.1972 |

| 3D printing | 1981 |

| Solid Ink printing | 1986 |

| Digital printing | 1991 |

What we are always looking for at Wild Thang is the next branding and product innovation. That search will always continue....

Read more